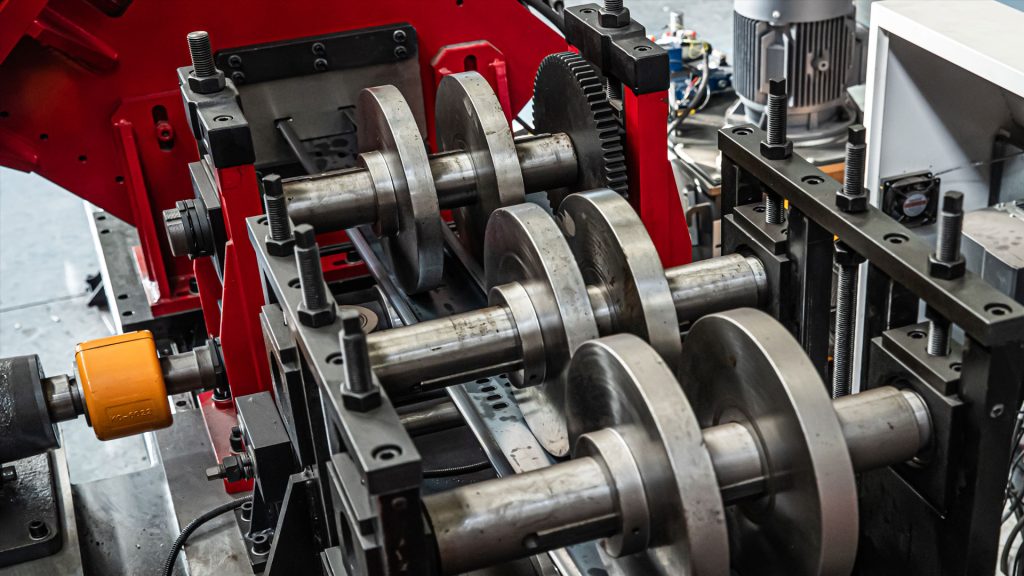

Strut Channel Roll Forming Machine

The rapid expansion of renewable energy sources, particularly solar power, has created a growing demand for durable and efficient structural components. Roll forming technology plays a crucial role in this sector by producing high precision metal profiles that support solar panels and other renewable energy infrastructure. The process ensures uniformity, strength, and cost-effectiveness, making it an ideal solution for large scale renewable energy projects.

Unistrut Machine

Roll forming is not only beneficial for producing structural components but also contributes to energy efficiency in manufacturing. Compared to traditional metalworking techniques, roll forming reduces material waste, minimizes energy consumption, and enhances production speed. These factors lead to a more sustainable manufacturing process, aligning with the global goal of reducing carbon footprints in industrial operations.

Roll forming Lines for Solar Industry

Solar farms require robust and long-lasting support structures to withstand environmental conditions and ensure optimal energy generation. Roll forming lines are specifically designed to produce high quality mounting structures and frames for solar panels. These customized roll-formed profiles provide superior durability, resistance to corrosion, and easy installation, facilitating the efficient deployment of solar farms worldwide.

Green Roll Forming

The concept of green roll forming emphasizes the integration of eco friendly materials and energy efficient processes into roll forming technology. By using recycled metals, optimizing production workflows, and adopting cleaner manufacturing techniques, roll forming contributes to sustainable industrial practices. As the renewable energy sector continues to grow, green roll forming will play a pivotal role in building a cleaner and greener future for energy production.

You must be logged in to post a comment.