Product description

The C/Z/U Purlin Production Line is engineered to deliver more than just basic functionality — each component is designed to add a competitive advantage.Profile specifications of Web: 50–250mm and Flange: 30–80mm ensure broad applicability across industrial and construction projects, offering maximum design flexibility.

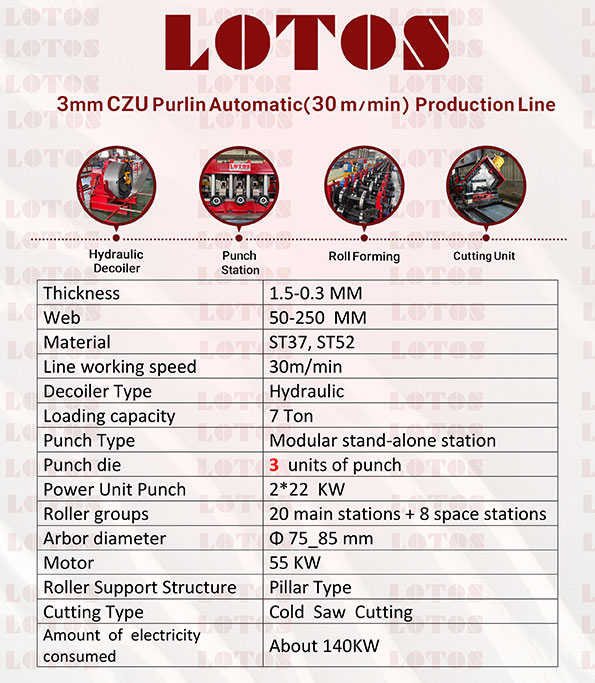

working flow:

Hydraulic Decoiler+Loading Cart → Looper 1# → Servo Feeding+5-roller Leveling +Hydraulic Punch Station (3 units of punch seats) →Looper 2# → Roll Forming Machine → Servo Tracking Cutting Die → Out-put table

FAQ:

1.What is the main difference between a CZU production line and a single profile line?CZU line can manufacture all three profiles (C, Z, and U) within one system, whereas single profile lines focus on only one type. This reduces investment costs, saves factory space, and increases production flexibility.

2.What measures have been taken to reduce wear and tear on the machine components?The use of CR12MOV rollers with advanced heat treatment, combined with a servo tracking cutting system that eliminates line stoppage, reduces mechanical stress and extends component lifespan.

3. What makes the punching system unique?The isolated punch frame, mounted on T-rails, minimizes vibration and ensures high-precision punching even at higher production speeds.

Reviews

There are no reviews yet.