Product description

Engineering Details & Line Performance

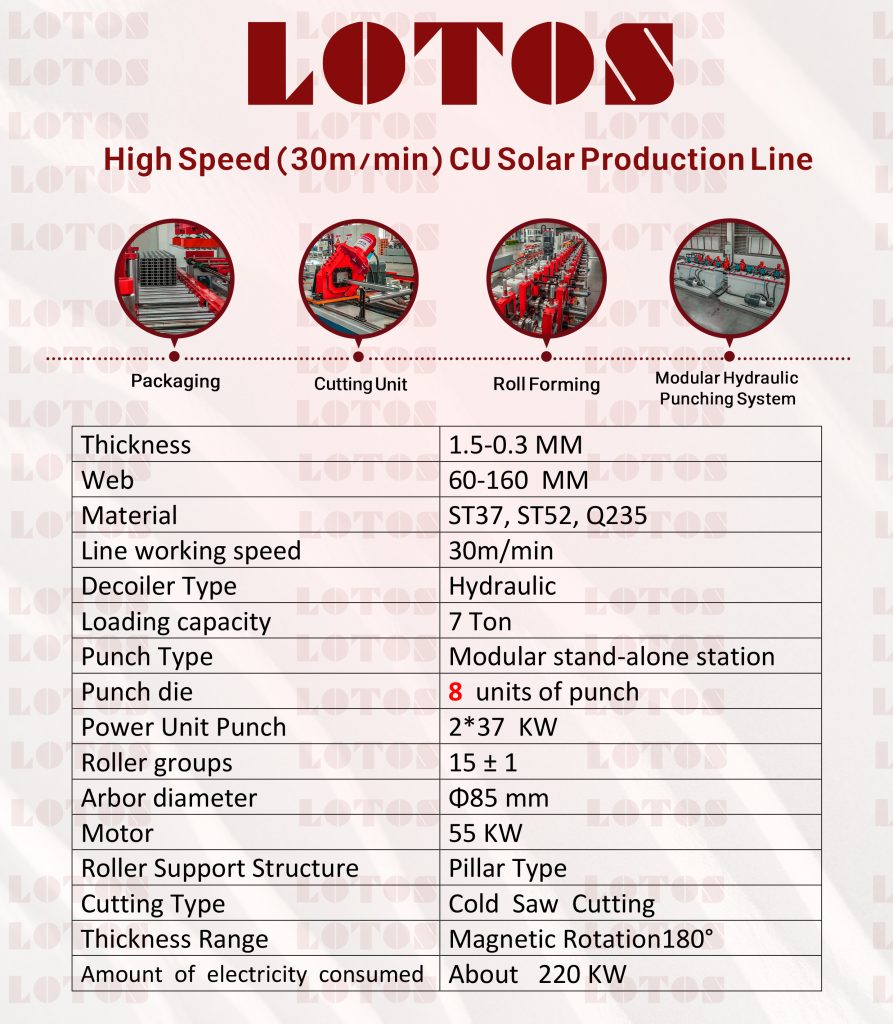

The C/U Solar Channel Roll Forming Line is engineered to manufacture structural profiles with high dimensional accuracy and superior mechanical strength. It is designed to process raw materials such as ST37, ST52, and Q235, with sheet thicknesses ranging from 1.5 to 3.0 mm, enabling the production of durable profiles suitable for solar applications.

The produced profiles cover a wide range of specifications:

- Web: 60–160 mm

- Flange: 30–80 mm

- Lip: 15–30 mm

The line operates at speeds of up to 30 m/min, supported by a flying cutting die, conveyor system, stacker, and an advanced electrical control cabinet, ensuring a continuous, precise, and highly efficient production process.

With its robust engineering design, the line guarantees consistent surface quality and profile uniformity. Its full automation minimizes manual intervention and provides the flexibility to meet the demands of large scale solar projects.

Additionally, the line is equipped with 8 independent punching stations.Despite the high number of punching operations, the integrated system design ensures that the production speed of 30 m/min is maintained without compromising efficiency.

working flow:

Hydraulic Decoiler+Loading Cart → Shear and Butt-welder → Horizontal Accumulator Leveling on Bridge Looper 1# Servo Feeding+5-roller Leveling+Hydraulic Punch Station (8 units of punch seats) → Punch Waste Collection Device → Looper 2# → Roll Forming Machine →

Flying Cutting Die → Conveyor Auto Stacker

FAQ :

1. How automated is the line, and which parts require an operator?

This production line is designed to be about 90% automated, and almost all stages including decoiling, feeding, forming, punching, cutting, transferring, and stacking are carried out by servo systems, magnetic clamps, and automatic conveyors.

The parts requiring operator involvement are:

Initial setup and product programming: setting feeding length, speed, and punching type.

Monitoring system performance: checking displays, sensors, and alarms.

Die change or minor maintenance: during punch die or flying-cut die replacement.

Quality control and final product collection: ensuring correct profiles and proper stacking.

Overall, the operator’s role is mainly supervisory and adjustment-oriented, with very limited manual intervention in the production process.

2. What infrastructure, such as power and hydraulic systems, is required?

For the installation and optimal operation of this C-Purlin production line, the following infrastructure is needed:

Power Supply:

Industrial three-phase power with voltage and amperage suitable for servo motors and auxiliary equipment, including servo motors (22 kW), dual-roller clamp motor (1.5 kW), and other auxiliary motors.Hydraulic System:

Hydraulic pump with adequate pressure for the hydraulic decoiler and other hydraulic equipment.

Standard oil tank and piping to ensure stable performance.Mechanical Infrastructure and Installation:

Flat, solid flooring for installing the line and supporting the main frame.

T rails for the movement of the stacker and magnetic clamp.

Sufficient space for loopers, conveyors, and the stacker.Control and Safety System:

Control cabinet with PLC and touch screen for line operation.

Grounding and electrical protection systems for operator safety.

With these infrastructures in place, the line can operate with maximum efficiency, high accuracy, and long-term stability.

3. Is the control system equipped with PLC and touch screen?

Yes, this production line is equipped with an advanced PLC control system and HMI (touch screen). The main features of the control system include:

Full line control: managing all sections, including servo feeding, roll forming, punching, flying-cutting, conveyors, and stacker.

Easy programmable settings: defining feeding length, punching numbers, line speed, and different profiles without mechanical changes.

Line status display: real-time information about motor performance, sensors, alarms, and production status.

Safety and protection: including emergency stop, fault monitoring, and automatic alerts for the operator.

Quick product changeover: fast switching between different profiles and saving production programs.

With this control system, the operator can manage the line accurately and intelligently, maximizing production efficiency and product quality.