Product description

High-Speed Solution for 90° C and U Purlin Profiles

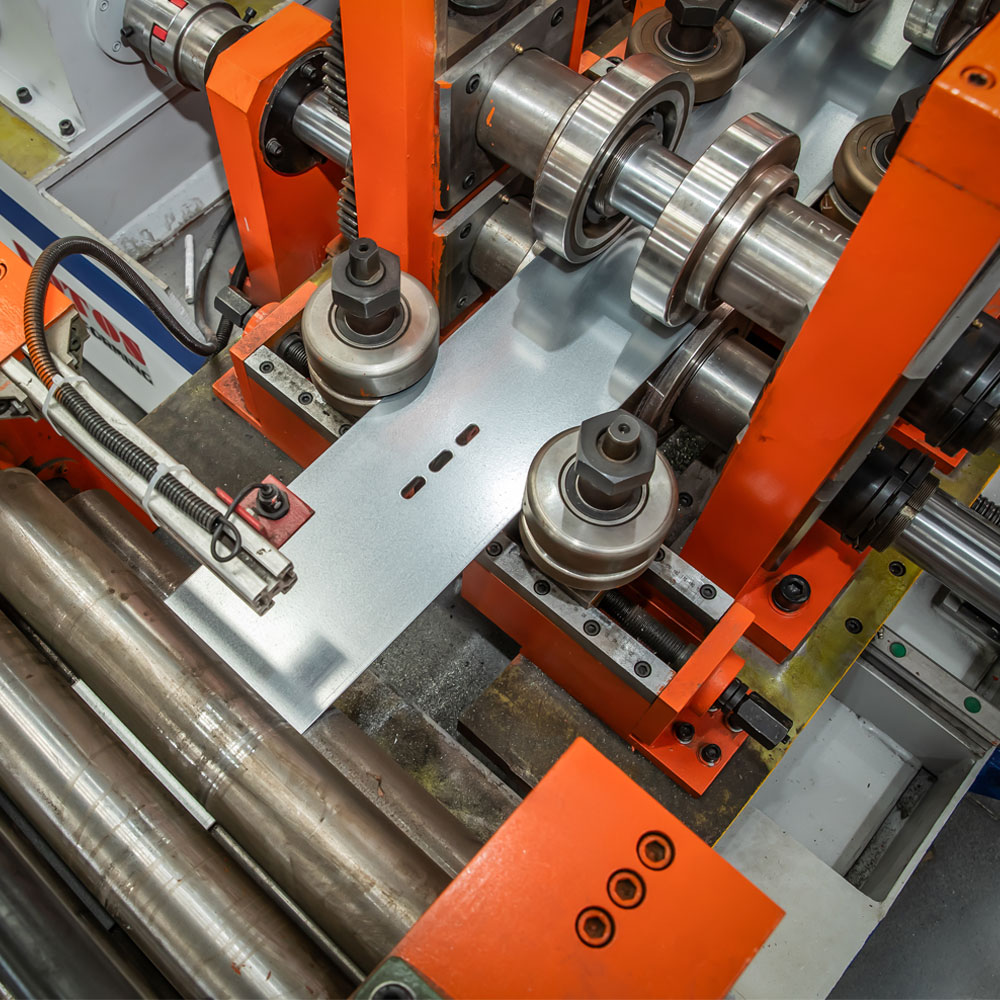

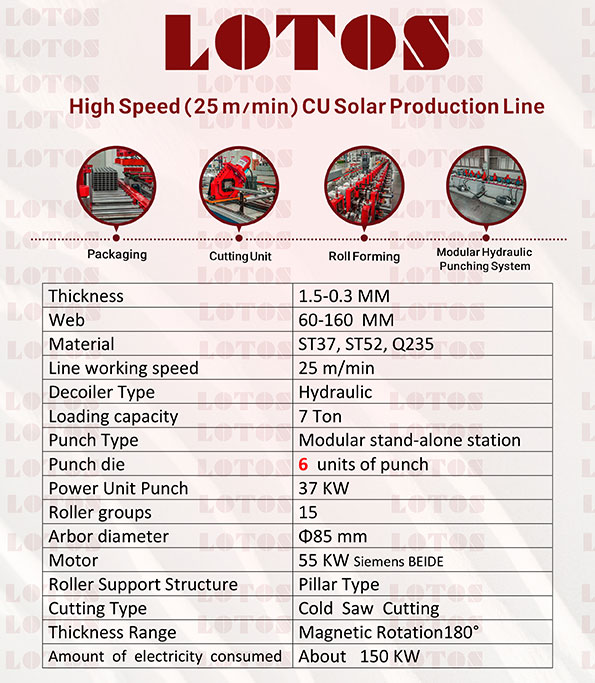

The 3mm C/U Purlin Roll Forming Production Line is specifically designed for manufacturing 90° C and U purlin profiles, ideal for solar and industrial structures. The line operates at a speed of 25 meters per minute, ensuring high efficiency and uniform production.

Profile Specifications:

Web: 60-160mm

Flange: 30-80mm

Web: 15-30mm

Raw Material Specifications:

Thickness: 1.5-3.0mm

With precise engineering and careful design, this roll forming line guarantees profiles with minimal tolerance and consistent quality,covering a wide range of industrial and solar structural applications.

working flow:

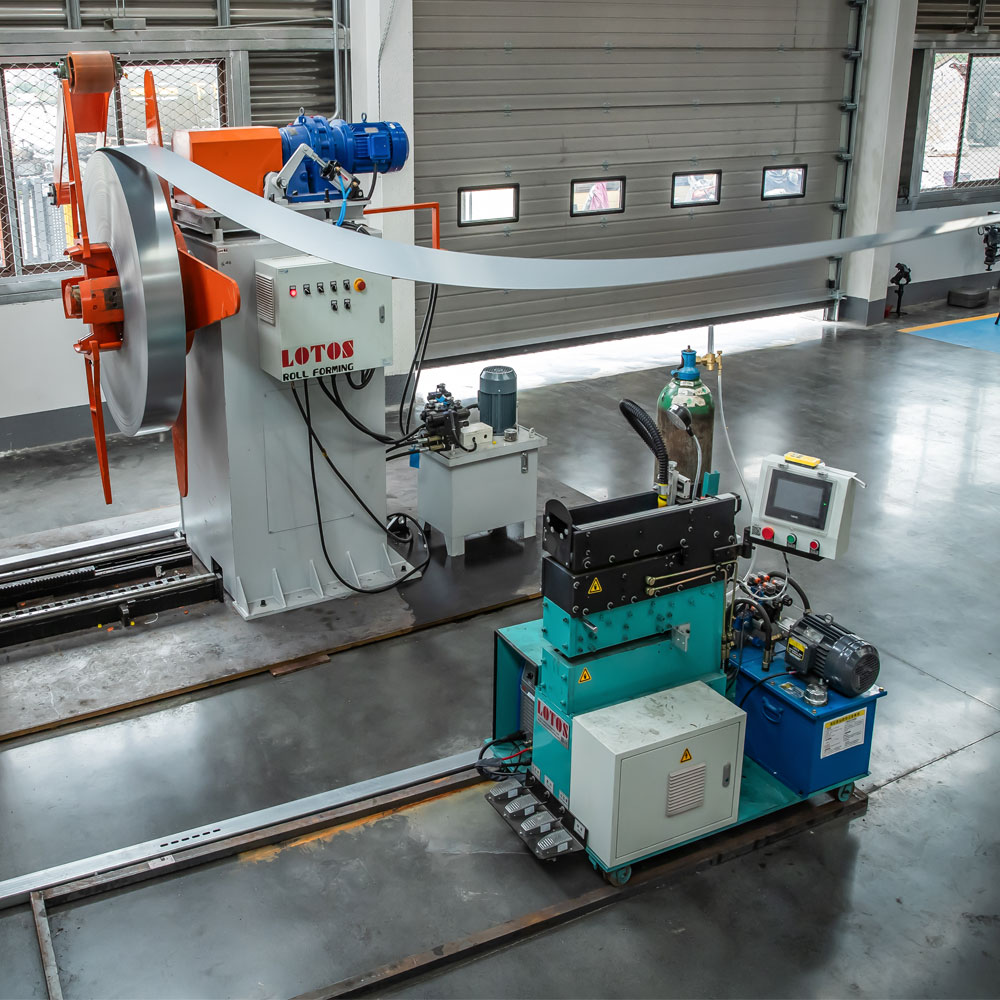

Hydraulic Decoiler+Loading Cart → Servo Feeding+5-roller Leveling+Hydraulic Punch Station(6 units of punch seats) → Looper → Roll Forming Machine → Flying Cutting Die → Run-out table

FAQ :

1.How is thickness and width/height adjustment done?Thickness change is done via a manual interchange tooling system, while width/height is fully automatic using servo motors and Hiwin T-rails

2. How safe and user friendly is the machine?

Servo systems and automation reduce manual intervention, enhancing both safety and ease of operation.

3.What advantages does this machine have over traditional production lines?With a high speed of 25 m/min and precise roll forming design, production efficiency and quality are significantly improved.