Roll Forming Machine VS Bending Machine

- Home

- Roll Forming Machine VS Bending Machine

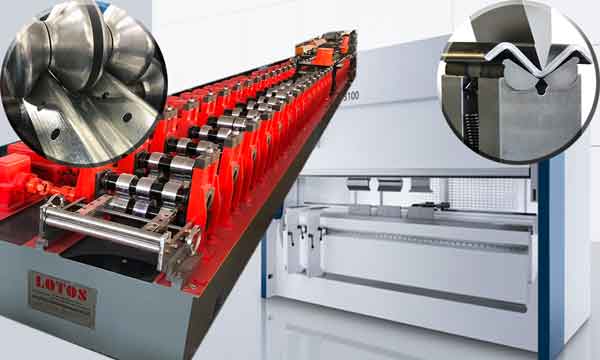

ROLL FORMING VS BENDING

1: ROLL FORMING VS BENDING: Roll forming is continues process for steel strips to make required section profile in any length as we all know bending has limited for length and will done through several steps not continuously.

2: roll forming machine can make close type section with roller efforts under proper design, but bending machine cannot make any close pattern section.

Analysis of Roll Forming vs Press Braking

3: the only advantages of bending machine vas last generation of roll forming Line is can produce profile with different section drawing among of length. For example, the 9-meter octagonal light beam just can produce by bending machine cause the strip width and section drawing is not same from bottom to top.

4: the advantages of new generation of roll forming vs old type is we can form different drawing section with one roll forming line by automatic roller change that old roll forming machine just produce one specific section of profile. So bending different size of section by same strips is not advantages any more compare with new roll forming machines.

5: for production time and energy usage with labor cost, for sure roll forming line are more economic and fast. One line of automatic roll forming can easily operate by 2 workers in normal speed (15m/min).

Roll Forming vs Press Braking

we wanna explain Roll Forming and Press Brake, Then provide a comparison between roll forming and Press Brake bending process. Roll Forming and Press Brake are Two processes with the same result. in sheet metal fabrication while you can see the bend it’s often not clear which method was used. However, roll forming and press braking are very different ways of getting the same result, and their economics are completely different too.

Press Brake Bending Process

press brake is a machine pressing tool for bending sheet and plate material, most commonly sheet metal. It forms predetermined bends by clamping the workpiece between a matching punch and die. features press brake bending:

- Press braking is efficient and cost-effective

- small volumes and with shorter part lengths

- Larger orders get expensive very quickly

- unable to handle longer parts

- brake press is normally easier to set up

- Brake press tooling is normally less expensive than roll forming or stamping

- difficult to provide value-added features like holes or punched shapes during the process

- the force of the die shaping the metal often leaves scrapes on sheet metal

Roll Forming Process

in roll forming the metal shape by stretching it through pairs of rollers that one of them supports the underside and other on the top surface. Each pair shape to provide a little more deformation. Therefore, geometry is increased a little more until the last pair produces the final shape required. by Using more complex roller shapes, it’s possible to put in multiple bends. important thing about the roll forming process:

- Works on the continuous coil

- No limit to the length of bend

- Bends must all be in the same direction

- Profiled lengths are cut to size after forming

- Tooling can be expensive

- The roll forming line needs to be set up by an experienced operator

- Roll forming performs best for projects that require medium to high volumes

Roll Forming Advantages Compared To Press Braking:

- The press brake is flexible and very versatile. Almost any bend can be put in, in practically any orientation.

- metal roll forming works on long lengths of coiled material but Brake Press material must be sheet This causes it a process for higher volume production while press braking is more of a low-to-medium volume process.

- Roll forming tooling costs are higher compared to other forming services

- roll forming allows for more in-line fabrication, medium to large runs, and higher volume orders

- more gradual forming sequence, roll forming produces extremely tight tolerances as well as an attractive finish

- roll forming process allows you to add tooling to create any shape, no matter how complex. Complex profiles can easily forme through the single-pass linear roll form process.

- Roll forming easily handles high volume orders and is more cost-effective at high volumes

- In addition to production efficiency, the keeping of part quality is critical to any customer delivery.

FAQ :

A roll forming machine shapes metal continuously through multiple roller stations, creating long and uniform profiles. A bending machine forms metal by applying force at specific points to create individual bends or angles.

Bending machines are suitable for short pieces, customized parts, prototypes, or jobs that require precise individual bends rather than continuous shaping.

No. Roll forming is best for continuous profiles, while bending is best for parts that require multiple unique bends or shorter lengths. Many factories use both machines depending on the project..

Both machines can work with similar materials, but roll forming machines are typically optimized for thin to medium thickness coils, while bending machines can handle thicker sheets for heavy-duty applications.