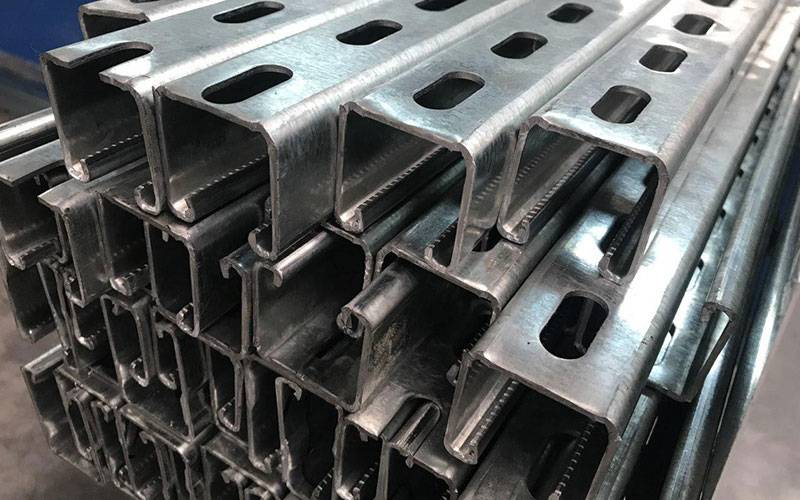

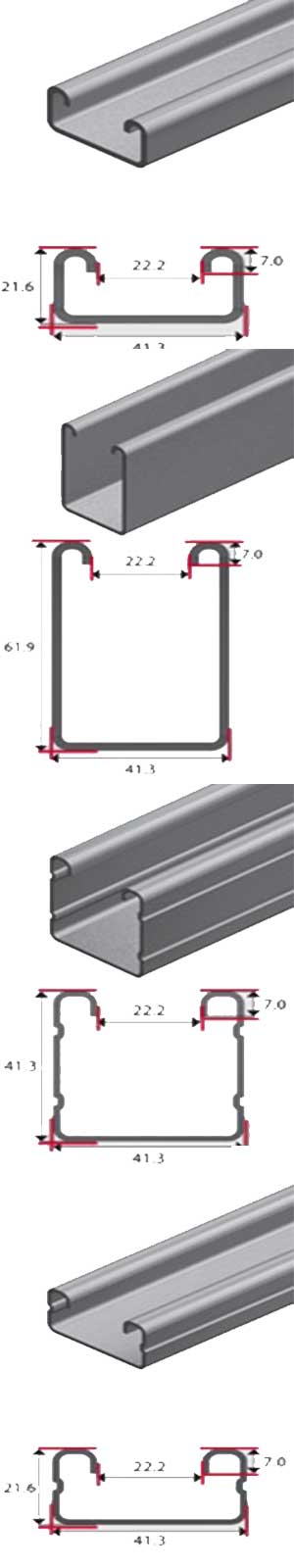

LOTOS ▷ Unistrut Channel Roll Forming Machine – Solar Frame 2024 produce all size of strut channel required for this purpose. With the maximum thickness and perfectly curved edges and the strut channels are of superior quality.

in fact, The main advantage of strut channels in construction is that there are many options available for rapidly and easily connecting lengths together and other items to the strut channel, using various specialized strut-specific fasteners and bolts. furthermore, They can assemble very rapidly with minimal tools and only moderately trained labor, which reduces costs significantly in many applications.in addition, A strut channel installation also can often be modified or added to relatively easily if needed. The only alternative to strut channels for most applications is custom fabrication using steel bar stock and other commodity components, requiring welding or extensive drilling and bolting, which has none of the above advantages.