U Channel roll forming machine

- Home

- U Channel roll forming machine

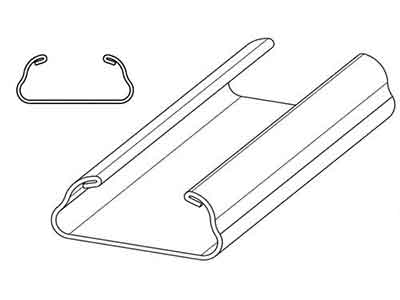

C channel roll forming machine

we can supply different kinds of roll forming machines.LOTOS manufacturers and suppliers Various ▷ U Channel roll forming machine | Ceiling furring channel ◁. To summarize, The U Channel Making Machine specially design to manufacture high-quality Side channel / U channels. in fact, We specialize in making all types and sizes of U channel machines and also customize ones as per the client’s needs. Our Steel U Profile Roll Forming Machine Favor By Customers All Over The World. Welcome To Buy Ceiling Channel Roll Forming Machine From Us. In addition to, This machine exports to many countries, the most important is that all you need can be customized.

Multi Size U Profile Roll Forming Machine

This cold roll forming machine designed to produce steel U channel sections with galvanized steel coils. consequently, The finest range of Roll Forming Machine made available by us in the market is manufactured in compliance with the set industry norms and guidelines.

U Channel Terms :

U Channel Depth: The distance from the top and bottom surface of the steel.

Flange Height: The top and bottom flat horizontal sections Web Thickness. The thickness of the vertical center section of a channel.

Fillet Radius: The curved portion, where the inside transition between the web and flange occurs call a fillet. The radius of the fillet is called the fillet radius. Steel Channel is a cold Rolling product.

Steel U Channel has the following application :

- Structural Channel: Used in varied construction and manufacturing projects.

- Ship & Car Channel: A set of sizes that were developed for the use in the construction of Marine Vessels and Automobiles.

- Stair Stringer Channel: A set of sizes that were developed for the use in the construction of Stair Casings U Channel or Bar Channel. A set of smaller channel sizes.

C profile making machine

U channels are suitable for use in structural applications or engineering, furthermore, offering properties such as increased strength and durability and are typically used to support floor joists.in fact, We supply U channel steel roll forming machine sections for industrial and construction applications. Steel U Track Roll Forming Machine available include bespoke and standard channels. moreover, the Steel U channel is light and strong and is available in both deep and shallow channels. Contact our team for more information about Ceiling Channel Roll Forming Machine. LOTOS COMPANY can produce the following Machine:

- ceiling channel roll forming machine price

- c channel roll forming machine

- pop channel roll forming machine

- ceiling channel roll forming machine

- furring channel roll forming machine

- channel roll forming machine

Greenhouse Film Lock Channel Making Machine

Greenhouse wiggle wire and lock channel is a fast and safe method to install polyethylene plastic in your greenhouse. Poly Lock Channel and Spring Wire work together to create the best and fast greenhouse film lock method. Simply install the Poly Lock Channel and wiggle the wire back and forth over the top of the material you are installing and into the channel. Galvanized steel Wire Lock use to fasten poly film or shade cloth to your greenhouse. It is an aluminum base channel.

Conductor Bar Roll Forming Machine

LOTOSFORMING is one of the most experienced Copper Channel Machine manufacturers in China. Cast In-Channel Machine is used to produce Crane Shrouded Bus Bar Conductor Rails. The conductor bar roll forming machine includes decoiler, feeding, main forming machine, saw the cutting device, outer table, and electrical control system.

Curtain U rail roll forming machine

curtain guide rail offer more precise motion control and TOP QUALITY, MORE REASONABLE DESIGN, EASY TO INSTALLthan spherical bearings, and greater rigidity for ease of movement.

U Curtain Rail Roll Forming Machine, innovative and computer-controlled, is used for U Curtain Rail, routing lock face holes, viewer holes. The curtain U rail forming machine is our new design. You can customize the size and model according to your requirements.

C profile machine

Summary

- Material: Galvanized Coil

- Material Thickness: 1.5-3mm

- Main roll forming machine Power: 11 KW

- Forming Speed: 5-10m/min

- Production line length: about 12m

- Dimension: 7×0.8×0.9 m (L*W*H)

- Weight: 5-7 T

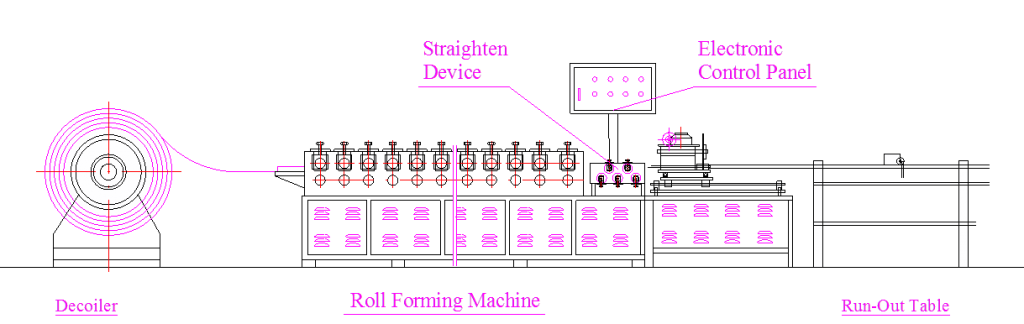

Main Parts Ceiling U Channel Machine

- Manual 3T uncoiler

- Feeding Guide

- Roll Forming System

- Hydraulic Cutting

- Control system

- Output table

Working Flowing

Manual Uncoiler —> Feeding —> Roll Forming —> Cutting —> Output

C Profile Roll Forming Machine

Machine details:

| No. | Description | Specification | |

| 1 | Performance | Transmission type | Servo motor + chain |

| Hydraulic station motor power | Approx 5.5kW | ||

| Productivity | Approx 33m/min | ||

| Accuracy | ±1mm | ||

| 2 | Main machine | Roll former station | Approx 14stations |

| Roller material | GCr15 bearing steel chromed | ||

| Side plate | Aluminum alloy with anode treatment | ||

| Spindle material | 40Cr thermal refining | ||

| 3 | Punching | Before forming | Hydraulic cylinder pre-punching |

| Punch material | Cr12MoV | ||

| Mould quality | 6Nos | ||

| 4 | Cutting | After forming | Hydraulic cylinder profile-cutting |

| Blade material | Cr12MoV | ||

| Mould quality | 1Nos | ||

| 5 | Control | Production | Windows 8 |

| Commissioning | Wireless remote | ||

| 6 | Decoiler | Automatic decoiler | Electrical expansion |

| Loading capacity | Max. 3tons | ||

| Internal diameter of coil | 430mm-590mm | ||

| Outer diameter of coil | Max. 1300mm | ||

| Width of coil | Max. 450mm | ||

| Thickness of coil | 0.75-1.2mm | ||

| Raw material of coil | G550 | ||

FAQ:

These machines can handle cold-rolled steel, galvanized steel, stainless steel, aluminum, and other alloys, depending on thickness and application requirements.

U channels are widely used in construction frameworks, ceiling grids, door and window frames, cable trays, solar panel mounts, and shelving systems.

LotosForming provides customized solutions, robust machinery, CNC roller design, and expert after sales support, ensuring reliable, long-term performance for all production needs.

These machines are designed for continuous, high-speed production, making them ideal for large-scale manufacturing while maintaining consistent quality.