Uncoiler Machine

- Home

- Uncoiler Machine

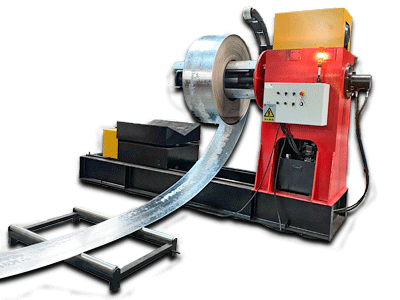

Motorized Decoiler

If you have any machine that will run using coils, you Certainly need an uncoiler or decoiler. for example, if you have roll forming, stamping, or slitting lines, a decoiler require to unroll the coil for the next process. decoiler machines always design based on specifications from the steel coil industry. LOTOS is a leading Manufacturer of Feeder machines, Decoiler & Uncoiler machines, Straighteners machines, and so on.

There are different decoilers or uncoilers according to driven solutions, for example, manual decoiler with no power, electrical decoiler with a electric motor, and hydraulic uncoiler with a electric motor and hydraulic oil pump. LOTOS normally provides a manual decoiler as a standard decoiler. We use high-quality raw materials that procure from the certified vendors of the industry.

LOTOS produce all kind of decoiling machine such as: A motorized decoiler is a heavy-duty decoiler develope for high-speed production. and hydraulic uncoiler also is for heavy-duty or high-speed roll forming machines, high-speed slitting, and cut-to-length lines, and heavy-duty metal sheet embossing machine lines.

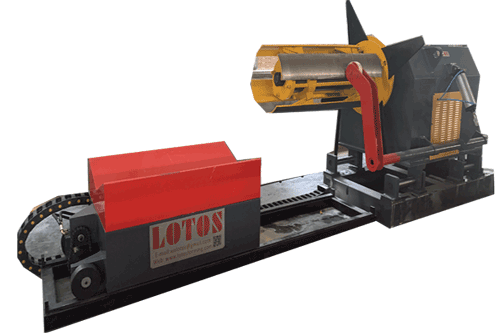

Double Head Decoiler

Double Head Decoilers design to minimize the coil loading time. While one head is uncoiling the coil, the second head is keeping the coil ready. once the first head finishes the uncoil process, the second head starts to uncoil

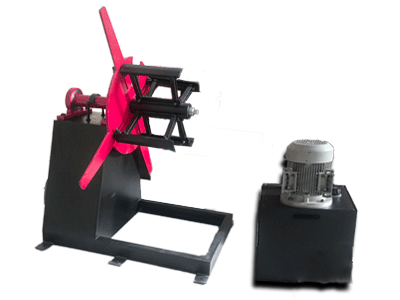

Manual decoiler:

A manual decoiler is a fundamental piece of equipment used in metal forming and fabrication processes. It is designed to hold and feed coils of metal sheets or strips into roll forming machines or other processing equipment. Unlike its automated counterparts, a manual decoiler requires the operator to manually control the tension and feeding speed, offering greater flexibility for smaller scale or customized production runs.

A hydraulic decoiler is an advanced piece of equipment designed for efficiently handling and feeding large coils of metal sheets or strips in industrial manufacturing processes. Powered by a hydraulic system, this decoiler automatically adjusts tension and speed, ensuring smooth, consistent material feed into roll forming machines or other processing equipment.

Motorized decoiler:

A motorized decoiler is a crucial component in automated metal processing systems, designed to handle and unwind coils of metal sheets or strips with the assistance of an electric motor. This type of decoiler offers automated control over the feeding speed and tension, ensuring a consistent and smooth delivery of material to roll forming machines, stamping presses, or other processing equipment.

Double Head Decoiler :

A Double Head Decoiler is an essential piece of equipment used in metal processing and fabrication industries. This device is designed to hold and uncoil two coils of sheet metal simultaneously, allowing for continuous feeding into a production line with minimal downtime. The double head configuration enhances efficiency by enabling one coil to be loaded and ready for use while the other is being processed, ensuring uninterrupted material supply.

FREQUENCY QUESTION ABOUT DECOILER MACHINE:

Decoiler or Uncoiler is one type of coil management equipment, used to keep and safely uncoil the steel strip. It is located at the beginning of a metal coil production line, generally configured with a sheet metal straightener and press feeder.

How does a decoiler work?

decoiler used to hold and safely pay off or uncoil the steel strip. Coiler controls the speed and direction of the strip of metal and is sent to the line for processing, such as slitting or tube mill entry also roll forming entry.

How many types of Uncoiler machines?

How to choose the right uncoiler machine for me?[/vc_column_text]

Hydraulic decoiler with loading cart:

| Loading capacity | 5T |

| Steel coil I.D. | φ480-φ520mm |

| Steel coil O.D | max φ1500mm |

| Cantilever width | 1000mm |

Manual decoiler :

| Loading capacity | 5T |

| Steel coil I.D. | φ508-φ610mm |

| Steel coil O.D | max φ1600mm |

| Max coil width | 1219mm |

FAQ :

1-What are the types of uncoiler machines?

There are several types of uncoilers, including:

Manual uncoiler – simple and cost-effective.

Motorized uncoiler – powered for smooth and steady coil feeding.

Hydraulic uncoiler – equipped with hydraulic expansion and braking systems.

Double-head uncoiler – allows quick coil change without stopping production.

2-What industries use uncoiler machines?

Uncoilers are widely used in metal processing, construction, automotive, appliance manufacturing, and steel coil handling industries.

3-What is the function of an uncoiler in a roll forming line?

In roll forming production, the uncoiler holds the steel coil and feeds it consistently into the roll forming machine. This ensures uninterrupted operation and prevents material damage.