Basic Roll Forming Design

The basics of roll form tooling design

we want to teach you something that none of the companies in the world ever teach you!

we want to step by step teach you how to design a forming machine. each new tooling requirement in a roll form design, take the following five steps:

1. Develop a cross-sectional drawing.

2. Calculate the estimated strip width.

3. Produce a bend progression, or “flower” pattern

4. Layout and design the roll tooling around the flower.

5. Incorporate tooling accessories

Roll Forming Design Guide

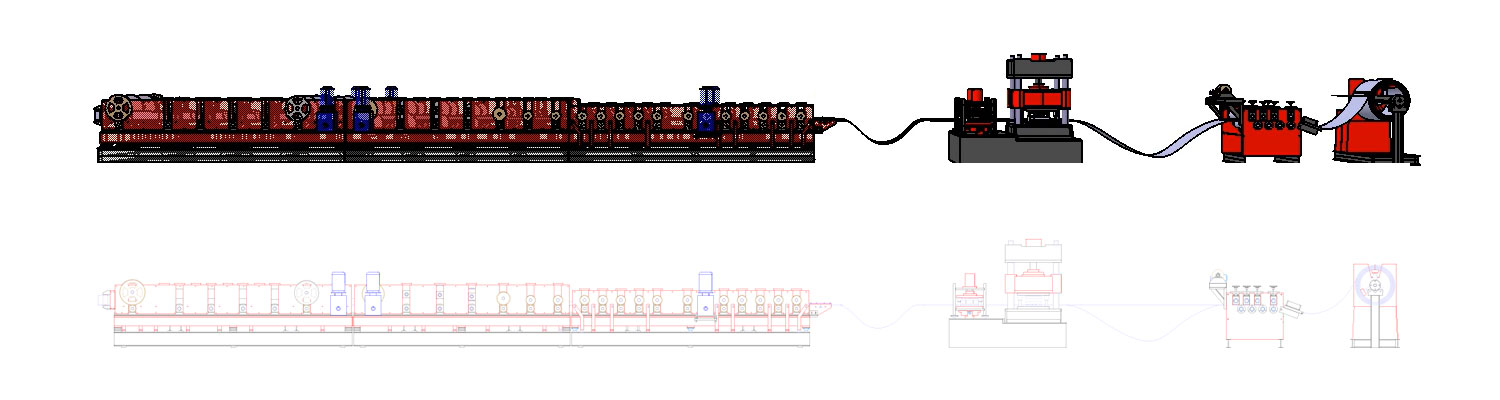

Before delving into the design of roll-forming rollers, it is essential to understand the basics of roll form design. Roll forming is a continuous process that involves feeding a metal sheet through a series of rollers. Each roller in the series gradually bends and shapes the metal into the desired form. The final shape is achieved by the cumulative effect of the rollers.

At Roll Forming Design Guide, we specialize in delivering high-quality, innovative solutions for the roll forming industry. Whether you’re a manufacturer looking to optimize your production processes or an engineer seeking advanced design tools, we provide the expertise and resources you need to excel.

Develop a cross-sectional drawing

The roll forming design process begins with a cross-sectional drawing. that serves as a kind of blueprint of what your profile’s shape and dimensions should be. On the drawing, you should note each bend’s radius and arc length, straight lengths, and material thicknesses.

Step 2

Calculate the estimated strip width

for calculating the strip width of the profile you should Use the proper “K” factor or “Bend Allowance” which is the main item.

Various factors contribute to the bend allowance, such as material type, material yield strength, profile characteristics, and roll design techniques.

Roll Forming Process

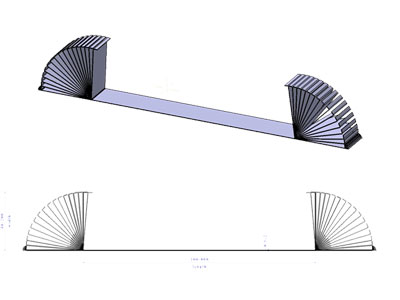

Step 3: Produce a Bend Progression, or “Flower” Pattern

With the strip width calculated, you can now create a bend progression, often called a “flower” pattern. This pattern visually represents each stage of the bending process, showing how the flat strip of material will be gradually shaped into the desired cross-section. The flower pattern is essential for planning the roll tooling and ensuring a smooth, consistent forming process.

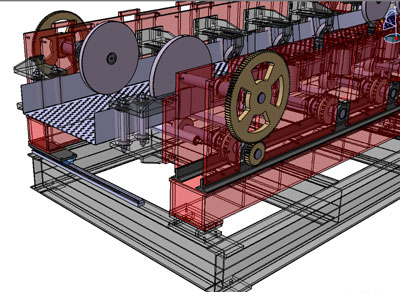

Step 4: Layout and Design the Roll Tooling Around the Flower

After finalizing the flower pattern, it’s time to layout and design the roll tooling. This involves creating detailed drawings of the rolls themselves, specifying the shape, size, and positioning of each roll to match the stages of the flower pattern. Precision is key here, as the rolls must work together in perfect harmony to form the material correctly without causing defects or unnecessary stress.

Step 5: Incorporate Tooling Accessories

The final step in roll form tooling design is incorporating any necessary accessories. These may include side rolls, edge guides, or special cutting or punching tools integrated into the roll forming line. These accessories are essential for achieving the