in fact, Using the technical knowledge of engineers, the LOTOS company has the ability to manufacture any type of High thickness roll forming machine.

High thickness roll forming machine to produce very thick profiles for custom usage. including:

8 mm Heavy Duty Purlin Roll Forming Machine

very thick L angle roll forming machine

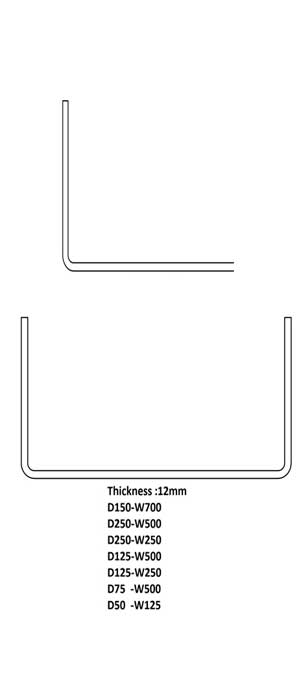

12 mm U & L Roll Forming Machine

heavy duty structural profile roll forming machine

High thickness roll forming machine

High thickness forming machine

5mm Thickness Automatic C Purlin Roll Forming Machine

The 5mm thickness automatic C purlin roll forming machine is designed to process steel sheets of up to 5mm thickness. This machine is highly efficient and fully automated, allowing for continuous production of C-shaped purlins used in construction frameworks. It offers precision cutting, punching, and forming capabilities, making it ideal for large-scale projects requiring sturdy and reliable building components.

Heavy Duty Roll Forming Machine

Heavy duty roll forming machines are built for tough applications that require the processing of thick and hard metals. These machines are engineered to handle materials of greater thickness and strength, such as structural steel, and can produce profiles used in demanding industries like construction, automotive, and shipbuilding. Their robust construction ensures consistent performance under heavy loads.

Roll Forming Machinery Suggested for Heavy Duty Work

For tasks that require the formation of thick and strong metal profiles, specific roll forming machinery is recommended. Heavy-duty machines, equipped with advanced hydraulic and control systems, are ideal for high-strength applications. These machines are suggested for industries where precision, durability, and high productivity are essential to meet the rigorous demands of heavy-duty work.

C Channel Roll Forming Machine

C channel roll forming machines specialize in the production of C shaped channels used in various industries, including construction, automotive, and infrastructure. These machines are highly automated and capable of producing channels with high accuracy and consistent quality. With features like adjustable width and thickness, C channel roll forming machines offer flexibility in production and can cater to different profile specifications.

Very Thick Roll Forming Machine

C/U Purlin Interchange Roll Forming Machine

Ⅰ. Production working flow

Hydraulic decoiler à feeding guide + 7-roller leveling+2 heads hydraulic punch die +hydraulic pre-cutting die à roll forming machine à output table

Ⅲ. Machine design capacity

- Raw material thickness: 1.0-4.0mm

- Raw material yield limit: 245MPA

- Forming speed: 3_7 m/min

Ⅳ. Machine components This production line will be combined with hydraulic decoiler, leveling system, servo feeding device, punch machine with dies, pre-cutting die, roll forming machine part, hydraulic cutting unit, output table, hydraulic oil pump, and electrical control cabinet.Ⅴ. Technical parameter1. Hydraulic decoiler (option) 1.1 Loading capacity 5T 1.2 Steel coil I.D. φ480-φ508mm 1.3 Steel coil O.D max φ1400mm 1.4 Function Hydraulic expansion, motorized unwinding 2. hydraulic Punch Station 2.1 Leveling roller 5 pcs 2.2 Leveling motor 5.5KW 2.3 Feeding unit XINJE 2.2KW servo motor 2.4 Punch unit 3 heads with dies,one die for waist, one die for bottom 2.5 Function Punch unit could move on rail with servo motor control for different position 2.6 Pre-cutting die Hydraulic 2.7 Mark Whole surface is well milled 3. Roll Forming Machine 3.1 Roller groups 16 stations 3.2 Roller material GCr15 with heat treatment, HRC58-62° 3.3 Roller shaft dia. Φ110mm 3.4 Shaft material 40Cr with quenching and tempering 3.5 Motor 22KW 3.6 Transmission way Gearbox 3.7 Machine frame body Integrated machine housing, surface well milled 3.8 Roller supporter casting pillar 3.9 Size change Servo motor, 2.2KW 3.10 C/U change Manual Interchange tooling system

| 4. Electricity control cabinet | ||

| 4.1 | Frequency inverter | DELTA |

| 4.2 | PLC | DELTA |

| 4.3 | Screen touch screen | DELTA |

| 4.4 | Low voltage | Schneider |

| 4.5 | Power | 380V/50HZ/3P |

| 5. Cutting System | ||

| 5.1 | Type of cutting system | Cut stop |

| 5.2 | Cut length tolerance | ±2mm |

| 5.3 | Engine power | 7.5 Hp |

| 6.Product table | ||

| 6.1 | type | Pneumatic |

| 6.2 | length | 12m |