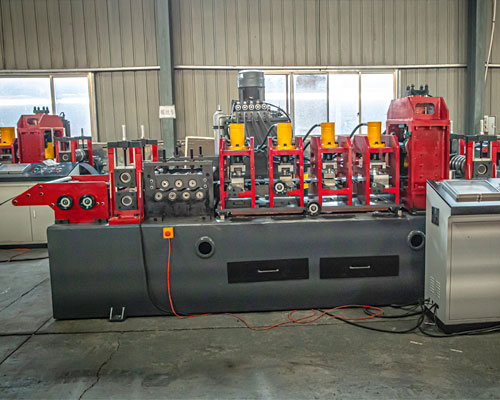

strut channel machine

In the modern roll forming industry, efficiency and precision are critical factors for success. The Automatic CU Channel production line, featuring a high speed capacity of 30m/min with multiple punching capabilities, is an advanced solution that meets industrial demands. This system is widely used in construction, infrastructure, and framing applications due to its speed, precision, and automation.

How Do Automatic CU Steel Channel Machines

The Automatic CU Channel Roll Forming Machine is designed to optimize production while maintaining high quality standards. Some of its key features include:

- High Speed Production: The machine operates at 30 meters per minute, significantly increasing manufacturing efficiency.

- Multiple Punching Stations: Equipped with an advanced hydraulic punching system, it ensures accurate hole placements without interrupting the production process.

- Precision Roll Forming: Utilizes high-quality rollers and guides for consistent CU channel dimensions.

- Fully Automated System: Features a PLC control system for seamless operation and reduced manual intervention.

- Customizable Designs: Supports various CU channel specifications to meet different project requirements.

solar panel bracing

Investing in a high speed CU channel roll forming machine provides multiple benefits, including:

- Enhanced Productivity: The ability to produce at 30m/min allows manufacturers to fulfill large orders quickly.

- Cost Effective Manufacturing: Reduces labor costs due to automation while increasing output efficiency.

- High Precision & Consistency: Ensures uniformity in CU channel dimensions, leading to better structural integrity in applications.

- Versatile Application: Suitable for drywall framing, ceiling systems, and lightweight steel construction.