What are the defects in the metal forming process?

1: each roll forming process line just can produce one shape profile with a range of thickness.

2: it needs feeler or wire gauges for the roller gap once raw material thickness changed.

What’s the stronger hot or cold rolled steel?

First of all we can not compare a hot rolling process with a cold rolling machine, each one has different duty for different material but generally we have much stronger cold roll forming line than a hot rolling line, meanwhile, there is so much small roll forming machine for law thickness profile.

As a result, we can tell you strong or weak base on the design of profile size and thickness.

Does cold rolling increase hardness?

No during stand rolling process the hardness of material won’t increase.

How is cold rolling done?

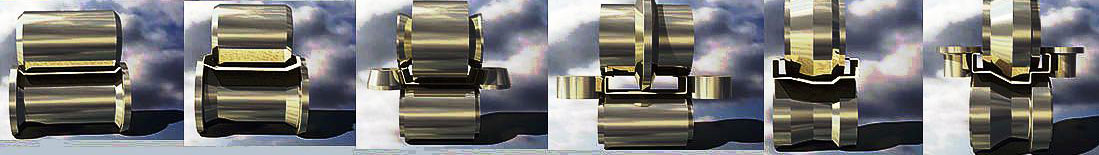

Its start by design then analyzing for roller, then machining and heat operation for shaft and roller, in same way frame welding and surface machining finally goes for assembly and manufacture complete cold rolling machine.

How does cold forming work?

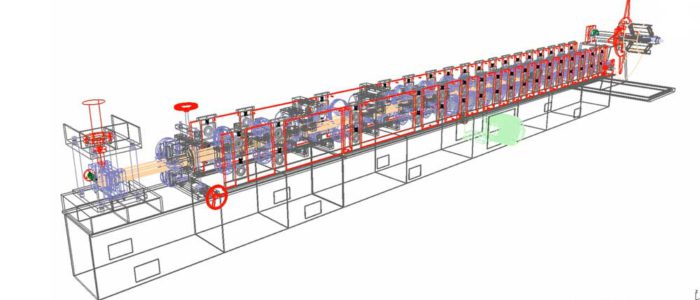

Cold forming machine feeding by sheet metal from de-coiler then start to forming step by step, stand by stand, each tooling stand has duty for a specific amount of changing shape on the raw material.

The most noteworthy point is roll forming machine working quietly without any popping or wrinkling, the further more final profile should be without any distortion, crimp as well as misalignment. All roll forming roller parts should design by experienced professional engineering with well-known software, to get the final standard result.

What’s Difference Between Hot Rolled Steel and Cold Rolled Steel ?

actually, Hot Rolled Steel vs. Cold Rolled Steel, Hot forming is a blend of extruding and rolling using fused steel under very high temperatures. Some structural shapes really cannot produce any other method except hot forming! such as : holding up and reinforcing buildings.

cold forming means making shapes at room temperature or a few above room temperature.flat and coiled sheets are raw material typically use through roll forming machines.