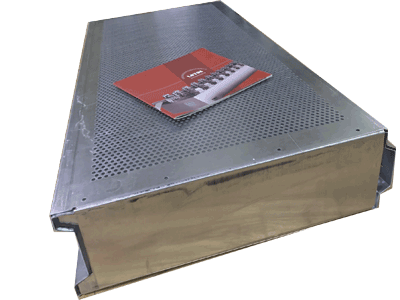

The Sound Absorbing Panels Roll Forming Machine or sound barrier making machine has the characteristics of fast production speed, less labor required, exquisite workmanship, and no scratches on the surface of the sound-absorbing. this production line consists of a feeding device, transmission device,and forming roller table and main machine,and cutting device after forming, and hydraulic system,and electric control system,and finished material holding device.

Roll Forming Machine in noise barriers roll forming machine or acoustic panel post roll forming machine has 18 stations Roller groups that make by 45# Steel, chrome coated with heat treatment. Roller shaft dia is 75mm and Shaft material is 45# Steel with quenching and tempering. the power of Motor is 7.5KW and the Transmission way is with Chain driven.In fact, LOTOSFORMING the company specializes in the research and development, design, manufacture, sales, and foreign trade of cold-formed steel, and is a professional manufacturer of cold-formed steel machines.